It is an uncommon occurrence for someone to come across a million cases of beer. Well, except in the case of HEINEKEN México.

When I learned that two recent graduates who met at our Implementing Industry 4.0 Course, Federico Crespo, CEO of Valiot.io, a fast growing industrial tech company, and Miguel Aguilera, Supply Chain Digital Transformation & Innovation Manager at HEINEKEN México, applied their learnings at the Monterrey brewery, and realized they could increase their monthly production significantly with the existing equipment, I was delighted — and intrigued.

How did they do it? Ultimately, they would use Valiot’s AI-powered technology to optimize the scheduling process in the presence of unpredictable events, drastically increasing the brewery throughput and improving worker experience; but it started with a proper diagnosis of the problem, using Little’s Law.

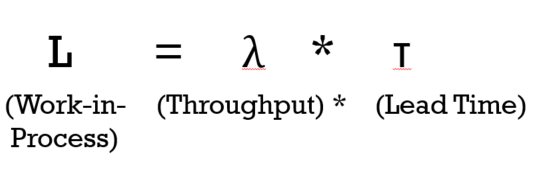

Little’s Law, often referred to as the First Law of Operations, is named for MIT Institute Professor John DC Little. He proved that in any system, the three most important properties of that system — throughput, lead time, and work-in-process — must obey the following simple relationship:

Little’s Law is particularly useful for detecting and quantifying the presence of bottlenecks and lost throughput in any system. It is one of the key frameworks we teach in MIT Sloan’s Implementing Industry 4.0 program.

Little’s Law in Action

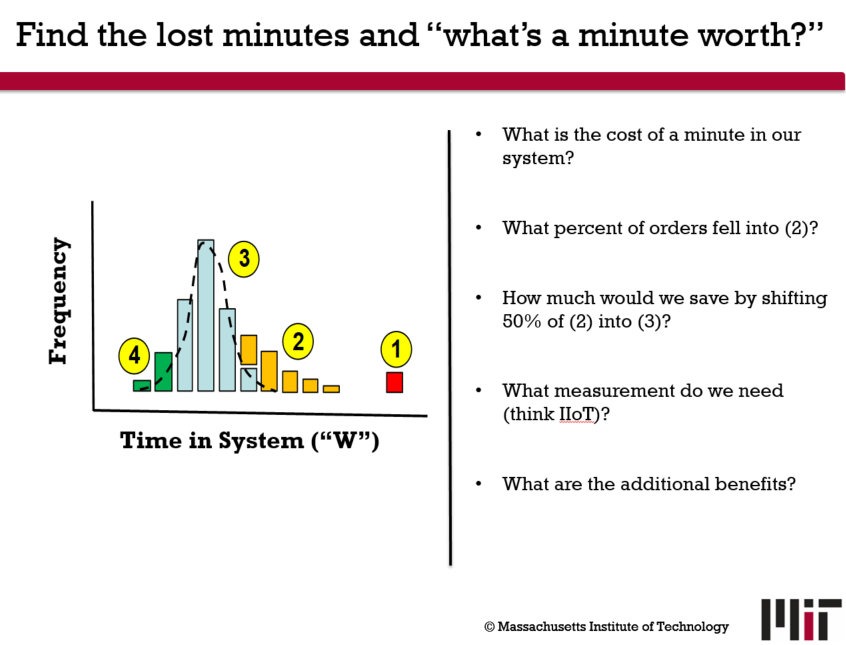

At HEINEKEN México’s largest production facility in Mexico, the two recent graduates applied Little’s Law and worked backward through the entire production process. They examined cycle times to assess wait times and identify the biggest bottlenecks in the brewery.

Specifically, they discovered a significant bottleneck at the filtration stage. As beer moved from maturation and filtration to bright beer tanks (BBT), it was often held up waiting to be routed to the bottling and canning lines, due to various upsets and interruptions throughout the facility as well as real-time demand-based production updates.

This would initiate a manual, time intensive re-scheduling process. Operators had to track down handwritten production logs to figure out the current state of the bottling lines and inventory by manually entering the information into a set of spreadsheets stored on a local computer. Each time a line was down, a couple hours were lost. With the deficiency identified, the facility quickly took action to solve it.

Bottlenecks Introduce Habits, Which Evolve into Culture

Once bottlenecks have been identified, the next logical step is to remove them. However, this can be particularly challenging, as persistent bottlenecks change the way the people work within the system, becoming part of worker identity and the reward system. Culture can act to reject any technological advance, no matter how beneficial this technology may be to the overall system.

Culture can also provide a powerful mechanism for change, however. As professor John Van Maanen teaches in our course, “Culture is a problem-solving device. People with similar problems develop similar cultures to solve them.” The best approach to introducing a new technology is to find early projects that reduce human struggle, which inevitably leads to overall improvements in productivity, reliability, and safety.

HEINEKEN México’s Digital Transformation

Working with Federico and his team at Valiot.io, and with full support of Sergio Rodriguez, VP of manufacturing at HEINEKEN México, Aguilera and the Monterrey brewery team began connecting the ERP and in-floor sensors to digitize the brewing process. Valiot’s data monitors assured a complete data quality interaction with the application. Fed by real time data, machine learning was applied for filtering and BBT process to optimize the daily-optimized production schedule. As a result, BBT and filtration time were reduced in each cycle. Brewing capacity also increased significantly per month. The return on the investment was clear within the first month of implementation.

The migration to digital has enabled HEINEKEN México to have a real time visualization of the bottling lines and filtering conditions in each batch. With AI constantly monitoring and learning from ongoing production, the technology automatically optimizes efficiency every step of the way. And, using the real time visualization tools, human operators in the factory can now make adjustments on the fly without slowing down or stopping production. On top of that, the operators can do their jobs from home effectively, which has significant benefits given current COVID-19 considerations.

The Key Practical Aspects

“[The Valiot team] needed to be on the floor with the operators to decode what they were doing. The algorithm had to be constantly tested against performance.”

According to Sergio Rodriguez Garza, Vice President Supply Chain for HEINEKEN México, success was ultimately based on the fact that Valiot’s approach was impacting the P&L, not simply counting the number of use cases implemented or discussing Industry 4.0 jargon – digitalization, sandboxes, digital twins, and so on. “The people who make the algorithms do not always know where the value in the facility is. For this reason, it is important to create a bridge between the areas in charge of digitization and the areas in charge of the process.”

“It is not yet systematic; each plant has a different bottleneck, and each needs its own diagnosis. However, the process of diagnosis is systematic, and each plant manager is responsible for his/her own plant’s diagnosis of the bottleneck.”

A unique diagnosis is key – and a quality diagnosis is based on a fundamental understanding of systems thinking.

What’s Next for HEINEKEN México?

HEINEKEN México has a clear mission toward a digital supply chain driven by data focused on empowering its teams on the shopfloor (not working harder, but smarter), as well as finding opportunities that have never been seen before with traditional way of working. It is not to digitize for the sake of digitizing; it is ensuring safety on the shopfloor, bringing initiatives that generate value to the business and most important, highly scalable among all the breweries and regions. “We’re now identifying the plant with the best CO2 performance with the intent of transferring the lessons to our entire portfolio.”

Key Takeaways

How did HEINEKEN México find and unleash this hidden capacity? The simple answer would be digital technology and a good technical ally, but that would leave out many of the key steps that made this project a success — diagnosis, systems thinking, and change management, to name a few.

The plant could have simply invested in more filters without taking the time to assess operational efficiency. The decision makers in this story took a lesson from MIT’s 60+ years of experience in System Dynamics, realizing that they could get more utilization out of their existing equipment while enriching the knowledge of the processes on their plant.

In other words, the real problem is not solved by buying technology but in knowing where to put it.

We have had the opportunity to work with companies from just about every industry, from food and beverage to software development, and we have learned that they all have one thing in common: hidden factories never run out of excuses.

A guiding purpose of MIT Sloan Executive Education is to provide professionals with practical frameworks they can put into practice immediately. The fact that this “mind and hand” approach is a mainstay of our programs does not detract from our excitement every time we hear a great story about our teachings in practice.

Implementing Industry 4.0: Leading Change in Manufacturing and Operationsis offered multiple times a year at MIT Sloan Executive Education. You can find more information and register here at the MIT Sloan Executive Education website.